Abstract

Concentrated solar thermal (CST) is a solar energy technology that uses sunlight to generate heat. CST systems use mirrors to concentrate a large area of sunlight into a small, targeted area, producing high temperatures. This heat is captured using a fluid, such as water, oil or molten sodium, which can then be stored for later use or used directly to create steam to power a turbine and produce electricity (also referred to as concentrated solar power or CSP). The heat can also be used directly to decarbonise industrial processes that use heat for the manufacture of products like fertilizers, fuels, ceramics, textiles or water purification and waste processing. One of the benefits of CST is that the captured heat can be stored cost-effectively for long periods with little loss of energy.

This means that CST can be used to generate electricity or provide heat when the sun isn't shining. Globally, most CST plants used for electricity production incorporate 3-15 hours of thermal energy storage. Spain is the world leader in the use of CST to produce electricity, with around 2.3 GW in operation, followed by the United States with around 1.7 GW in operation. This case study delves into the capabilities, innovative solutions, and impact of an Australian company, Sunrise CSP, that is contributing to global clean energy production by implementing solar thermal energy solutions.

Introduction

In 2023, one of India's largest cancer radiotherapy centres, the Kailash Cancer Hospital and Research Centre at Muni Seva Ashram at Goraj, Vadodara Gujarat installed the world's highest performance solar concentrator. The technology has been developed by the Australia National University (ANU) and the team from Sunrise CSP Australia, provides steam required for cooking more than 2,000 meals every day, apart from taking care of the hospital's laundry, sterilisation and bathing water needs.

ANU has been the first to develop and run a commercial solar thermal power plant, which was installed in White Cliffs, Australia in the 1980s and had 14 parabolic dishes of 20 m2 each. With over six decades invested in exploring solar thermal applications and developing increasingly sophisticated technologies, the university has always had strong focus on solar thermal research.

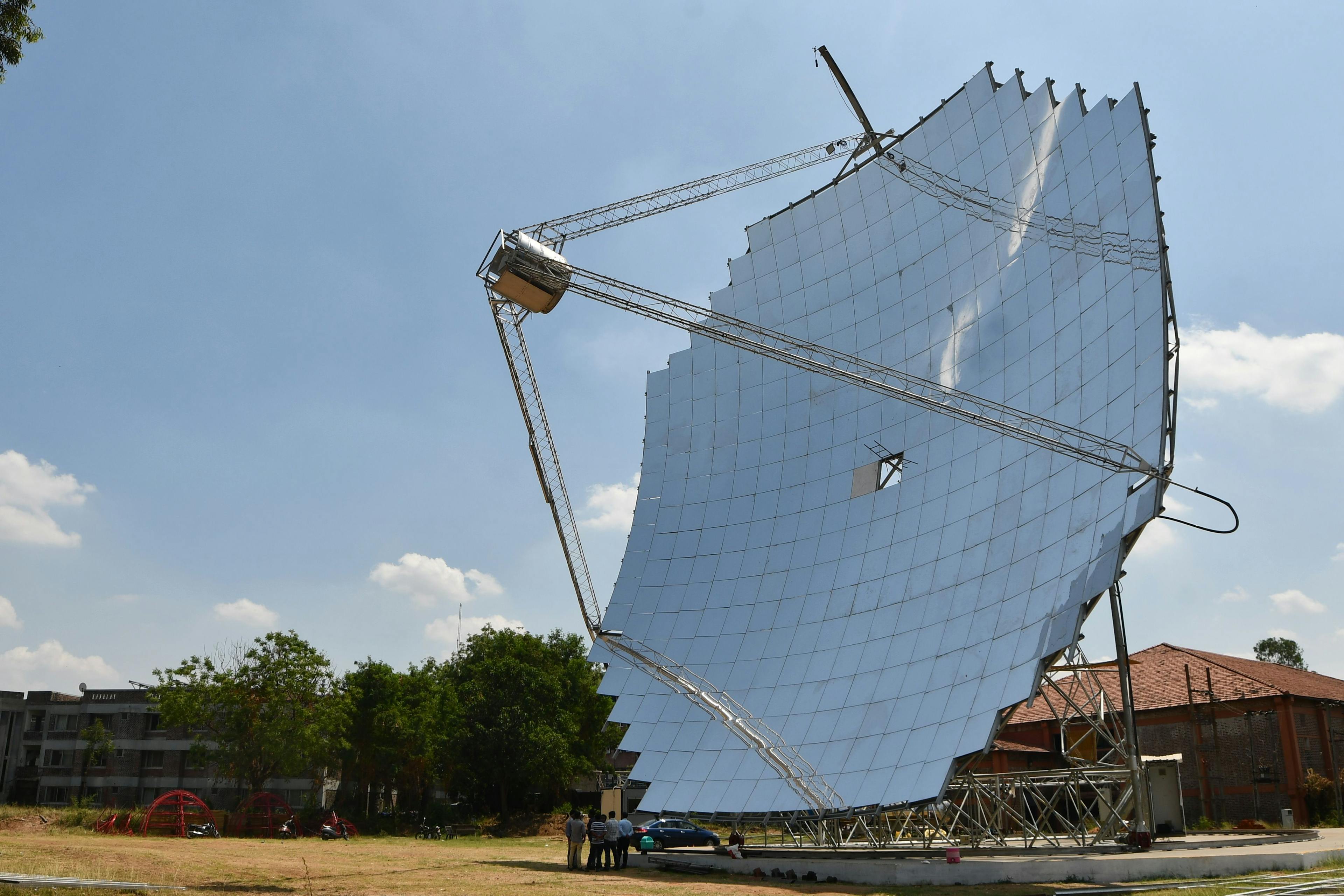

Following on the design of their previous prototypes SG3 (which is a 400 m2 dish), the SG4 solar concentrator was developed as a collaboration between ANU and Canberra based company Wizard Power, with support from an Australian Government's Renewable Energy Development Initiative (REDI) grant. It is a 520 m2 parabolic dish, making it the world's largest paraboloidal dish solar concentrator. The concentrator is a dual axis tracking parabolic dish with a receiver that can be installed on a small parcel of land of 25 m x 25 m.

The thermal receiver, designed and tested by ANU, provides record performance at >97 percent solar to thermal energy efficiency, with an accurate tracking algorithm ensuring efficient tracking of the sun to capture all the incident radiation. At the focal plane, the concentration at the receiver is 21 00x, allowing it to generate temperatures ranging from 150°C to over 1700°C. For steam applications, the SG4 receiver is designed to provide steam of temperatures up to 600°C, and at pressures of up to 160 bar. This can support the heat requirements for industrial-scale airconditioning, desalination, water purification, waste processing, and electricity generation.

Sunrise CSP Pty Ltd acquired the intellectual property for the Big Dish and its complementary technology in 2013. Apart from this, it also holds a patent on molten salt thermal storage technology, which enables continuous high-temperature steam delivery even when the sun has set or is obscured by clouds. The receiver is also designed for extremely high pressures, of up to 160 bar. The high performance allows the expansion of applications of solar thermal technologies, with the potential for use in the pharmaceutical industry, chemical industry, steel forming mills, etc., in ways which were earlier not possible.

The technology is designed for local manufacturing, using Sunrise CSP's Factory-in-the-Field (FiF) - which means that all Big Dish installations are made in India, on the project site, thereby, reducing solar field deployment costs, accelerating project development, maximising opportunities for local employment and suppliers and reducing supply chain risk by localising procurement. The FiF includes options for automation, labour content, equipment, and materials sourcing, which are adaptable to suit local circumstances and capabilities.

The FiF is a modular, scalable, reusable, and relocatable facility for the low-cost manufacture and assembly of the Big Dish space frame. It is designed according to the principles of waste elimination, repeatable quality, adaptability to local circumstances, rapid deployment, and continuous improvement.

"By adding modules, the FiF can be scaled from single dish industrial heat plants to hundreds of dish solar power plants, with the quality assured, using automated measurement processes at every stage of frame component manufacture and dish assembly. The quality and production metrics gathered for every dish and project enables Sunrise CSP's commitment to local adaptability and continuous improvement." -Artur Zawadski CEO, Global & Australia, Sunrise CSP Pty Ltd

India Strategy

In 2018, the developers of Dholera city, a Smart City in Gujarat, approached Sunrise CSP Australia to evaluate their Big Dish solar concentrator technology. They identified the Big Dish as a game changer in the provision of competitive and sustainable solar thermal energy for applications like freshwater production from seawater desalination, waste processing to eliminate pollutants and as a feedstock for manufacturing of chemicals and fuels, provision of district heating and cooling for the Dholera city, and grid-scale electricity generation. They considered this as a technology that could help realise Dholera's objective of creating an ultra-modern, inclusive, and sustainable city with a focus on people and their livelihoods. During this evaluation process, Sunrise CSP realised the potential of their technology and solutions in India - realising the Indian government's aim for net zero greenhouse emissions by 2070 and its National Solar Mission (NSM). The NSM focus is on creating a holistic solar ecosystem development, including development of solar manufacturing and solar technology R&D.

Setting its sights on penetrating the Indian market, Sunrise CSP embarked on finding a strategic partner. During this pursuit, they were introduced to Deepak Gadhia - renowned as the pioneer of Concentrated Solar Thermal Energy in India.

With both sides recognising the mutual potential and opportunities, Sunrise CSP India Pvt Limited was born as a subsidiary of the Australian company, with Deepak Gadhia as its inaugural Chairman and Pranav Gadhia, a builder of more than 100 solar thermal energy industrial projects, as its CEO.

The company was established in Gujarat, a state that is renowned for industrial development, business innovation and solar energy developments. Sunrise CSP India's first project commenced in 2020 for the Kailash Cancer Hospital and Research Centre near Vadodara, India's top rated cancer radiotherapy hospital - to fulfill its thermal energy needs for industrial laundry, cooking, sterilisation, bathing water, space cooling and electricity from the Big Dish thermal power plant.

The hospital was already a pioneer in the use of solar thermal energy for air-conditioning and cooking having installed 100 Scheffler dishes for that purpose in 2007. In 2023, the 1250 m2 of Scheffler dishes were replaced with a single Big Dish of 520 m2, which provided the same thermal output as the 100 Scheffler dishes, but with only 42 percent of the mirror area and while occupying only 33 percent of the land. The Scheffler dishes were installed on 2735 m2 of land, while the Big Dish occupied just 900 m2 of land.

Commencing in 2024, the project will be expanded to a 1,000 TR air conditioning system, which will be the world's largest solar thermal space-cooling system. The dishes will be integrated with chilled water storage and a biomass boiler for 24 x 7 operation, even in the monsoon period.

Sunrise CSP India Pvt Limited was initially established as a subsidiary of Sunrise CSP Australia, under Indian management and staffing. The Indian company's Board of Directors and Advisory Board are comprised of directors from Australia, India, and the USA. Its local Indian management and staff, and an international board, has provided the company with deep local market and business experience, and an international perspective on business strategy and governance. In 2020, the Sunrise CSP was capitalised by Australian, Indian and USA investors and Sunrise CSP International Limited was formed, in Cyprus, to be a global holding company. Sunrise CSP India was capitalised through this process and is now a subsidiary of Sunrise CSP International with Sunrise CSP Australia, as the technology owner, providing technology transfer and support services to India and globally.

The company engaged a Mumbai-based firm to develop its India market strategy and lead its capitalisation plan, concluding its first major international equity injection in 2020 and contract for the first commercial project in India and the world with the Kailash Cancer Hospital Research Centre in Gujarat. The company has customers across diverse sectors including textile, water treatment, waste management, and healthcare industries to meet their needs for industrial-scale steam and electricity.

The projects under development include integrating solar steam with the steam output of coal-fired boilers (reducing coal consumption), large-scale air conditioning, sludge drying, and desalination systems.

"The combined Sunrise CSP Australia and India management teams worked hand-inhand to devise our market entry strategy and identify the resources and advisors required to make it a success."

"We had two key objectives: - a successful market entry in India which would realise the first commercial implementation of our innovative technology anywhere in the world using the success of initial commercialisation of the technology and company growth in India as a springboard for global commercialisation of our technology, and with Indian and Australian engineering capabilities at the heart of our global expansion."

"We are very proud of the Australian and Indian management teams we have established to formulate our strategies and direct their implementation. This team has carefully developed the strategy with input and guidance from a diverse set of Indian and international experts in energy services, financial services, concentrated solar thermal technology and business management."

As an integral component of its expansion plan, Sunrise CSP is actively seeking an optimal investor partnership that prioritises strategic alignment and the achievement of mutually agreed-upon milestones. The company is currently open to investment opportunities, starting with a Pre-Series A round for US$2.5 million and followed by a Series A round for US$10 million. Additionally, there exists a prospect for funding various project Special Purpose Vehicles (SPVs), with estimated financial requirements of up to $1 O million over the forthcoming 3-4 years.

Recently, Engineers India Limited (Ell), India's large public sector engineering and project management consultancy has executed a collaborative agreement with Sunrise CSP, to leverage their combined expertise to deliver cutting-edge solutions in the field of concentrated solar and other renewable technologies. The partnership is positioned to accelerate the adoption of clean energy solutions, reduce carbon emissions, and contribute to the global efforts towards mitigating climate change.

Seeing The Future

The past few years have seen increased awareness on climate change and global growth in renewable energy. India has chalked itself tremendous solar energy growth plans in the pipeline. Rising electricity demand, falling prices for renewable energy, its push to manufacture solar photovoltaic modules, government support schemes aimed at boosting manufacturers' competitiveness and attracting investment (Production Linked Incentive schemes), and the waiver of transmission charges for renewable energy are the key drivers of India's renewable energy growth. The Institute for Energy Economics and Financial Analysis reports that the investment in renewable energy has hit record levels in India in the 2021-22 financial year, up by 125 percent compared with financial year 2020-21 and 72 percent higher than in the pre-pandemic period of the 2019-20 financial year.

India has one of the world's largest concentrated solar programmes, supported by the Ministry of New and Renewable Energy and United Nations Industrial Development Organisation (UNIDO), many industries have installed such systems. A study published by UNIDO in October 2018 showed that India has a 6.5 GW market of concentrated solar technology applied to industrial heat applications, aligned with the Indian government's programme to install 450 GW of renewable energy by 2030. The concentrated solar thermal (CST) technology is complementary to the solar photovoltaics (PVs) and wind used for electricity generation because it fills a gap that PV and wind cannot, through low-cost generation, storage, and delivery of pure, clean heat to industry.

"Sunrise CSP's primary goal is to make a major contribution to the successful achievement of India's renewable energy vision by delivering cost competitive, high value concentrated solar thermal energy as a complement to both traditional and new energy sources."

Planning Ahead

Photovoltaic solar panels can convert only 20 percent of the sunlight falling on them into usable energy in the form of electricity whereas solar concentrator technology, is able to use almost 90 percent of the sunlight that falls on the reflector of the solar concentrator in the form of heat. The technology is also helping in running 1,000-ton air-conditioning using solar steam instead of electricity for the 400-bed cancer hospital thereby reducing the cost of energy for the hospital and further lowering its greenhouse footprint by reducing its reliance on grid supplied electricity.

All this indicates a clear market demand for the technologies and thermal energy solutions offered by Sunrise CSP. Key learnings for Sunrise CSP in entering the India market were, how successfully they understand, navigate, and operate within the diverse set of community cultures, business cultures, and regulatory systems.

"The diversity and number of languages and cultures in India is vastly different to the Australian experience. The answer to succeeding in these circumstances is to establish partnerships with local people and trusted companies who share your vision. Our reasons for entering the Indian market have been reinforced over the 5 years since we commenced our journey."

Solar energy has been at the forefront of India's energy transition. Factors like scaling up of private sector investment, enabling policy and regulatory environment, access to affordable finance, technical training and capacity building, equipment quality control and standardisation will define the sector's growth going forward.