"We depend so much on space that we don’t realise, if it stops for a day, our entire economy halts."

Context & Opportunity

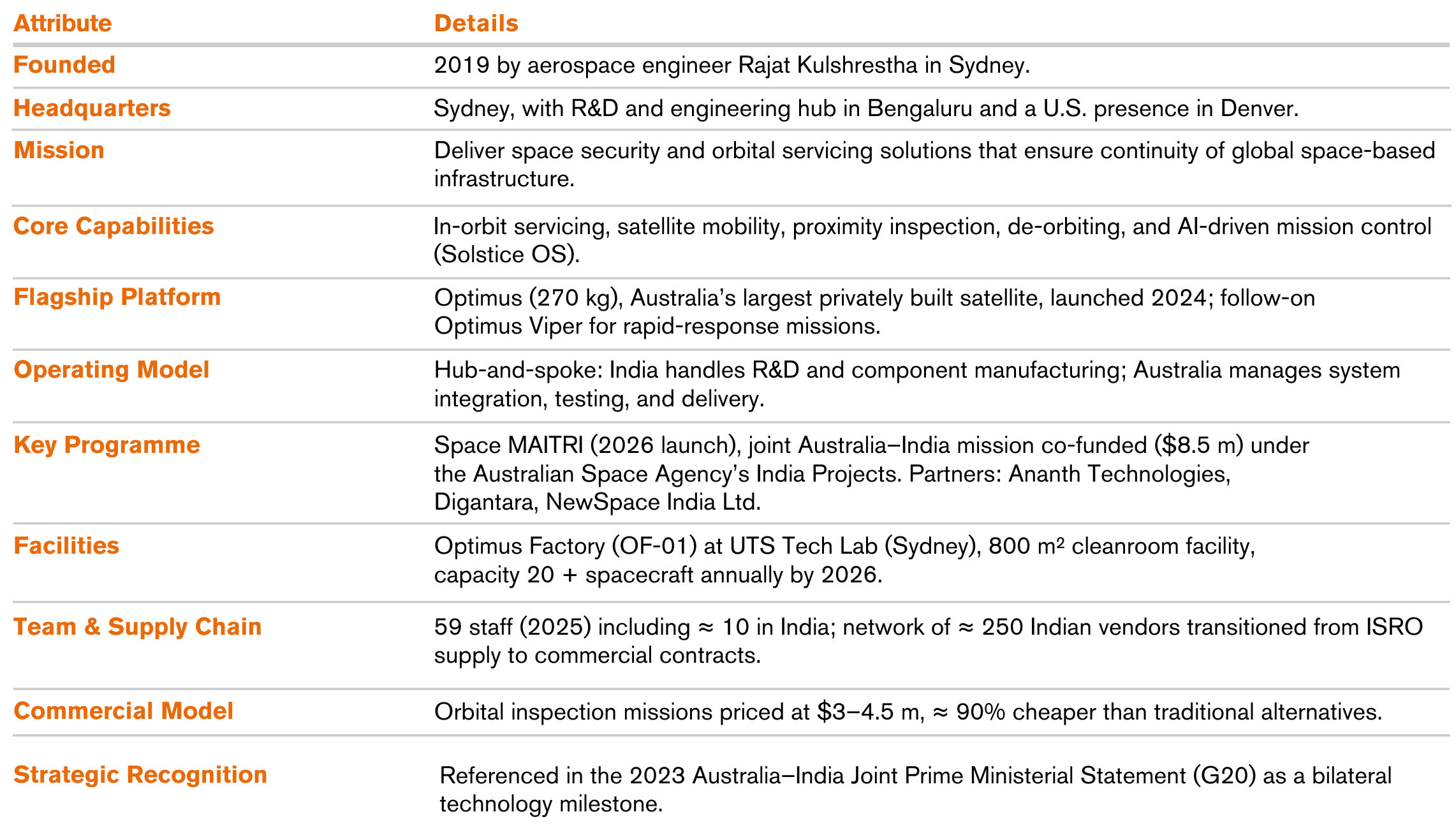

Founded in 2019 by aerospace engineer Rajat Kulshrestha and George Freney, Space Machines Company (SMC) has emerged as Australia’s leading orbital servicing and space mobility enterprise with a mission to ensure “space security and space superiority” for governments and commercial operators alike.

Headquartered in Sydney, SMC was established to solve a critical vulnerability in the modern economy, our growing dependence on space-based infrastructure without a means to maintain or protect it.

The company’s founder, an Indian engineer who migrated to Australia in the 1990s, embedded into SMC the Indian principle of Jugaad, resource-efficient innovation driven by determined dedication to outcomes. As he explained: “It’s not just frugal innovation. The superpower is the determined dedication to outcome; you have to get it done because there is no other choice.”

SMC built its first R&D hub in Bengaluru in 2019 with a former Team Indus lunar mission engineer as employee #1, an unusual move for a deep-tech company at inception. By 2025, SMC was operating from Sydney, Adelaide, Bengaluru, and Denver, positioning itself as the only non-US company offering orbital servicing and proximity operations.

The timing was strategic. Global launch costs had fallen from ≈ US$54,500 per kg (Space Shuttle era) to ≈ US$2,700 with reusable rockets, a 20× drop triggering an investment boom of US$12–15 billion in space start-ups by 2021 (Invest India 2024). Simultaneously, India’s 2020 creation of IN-SPACe opened the sector to private players, while the Australia–India Economic Cooperation and Trade Agreement (AI-ECTA) strengthened technology and defence links.

India’s space economy valued at US$2.54 billion and growing ≈ 15% annually (Invest India 2024), offered both cost and capability advantages. For SMC, this was not a cost-arbitrage move but a capability strategy.

Strategy & Execution

Greenfield entry model

SMC adopted a greenfield entry approach, building its Bengaluru R&D hub in 2019 and hiring locally from India’s lunar program to embed domain expertise from day one.

The company implemented a hub-and-spoke operating model:

- India handles R&D, component manufacturing, and supply chain operations.

- Australia performs system integration, testing, and global client delivery.

This “circular economy” model allows components built in India to be integrated into Australian spacecraft and re-supplied for Indian clients, ensuring mutual capability development and shared value. By 2025, SMC had ≈ 10 employees in India and 50 globally, supported by 250 Indian vendors transitioned from ISRO-exclusive contracts to commercial supply chains.

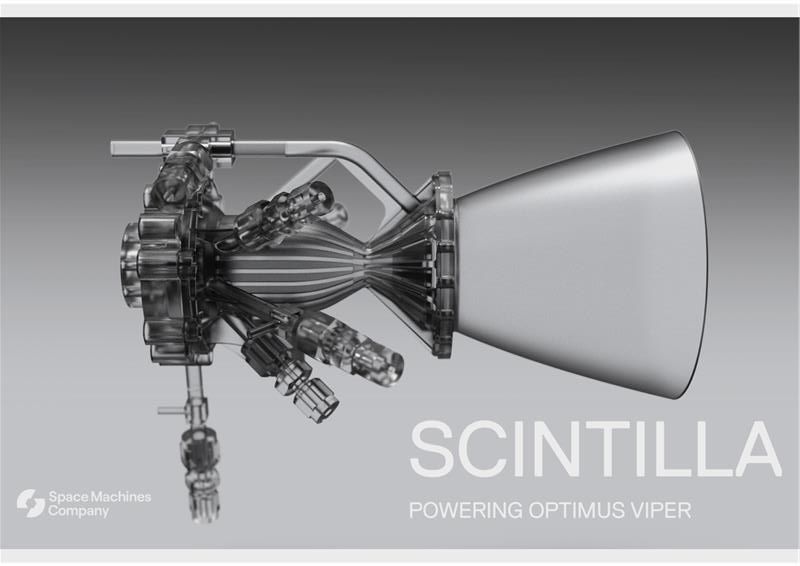

SMC’s core technology is its Optimus orbital-servicing vehicle, capable of proximity operations within 10 km of target satellites and payload transport in Low Earth Orbit. The first Optimus spacecraft (270 kg) launched in March 2024, the largest privately built Australian satellite (Australian Space Agency 2024). Following mission learnings, SMC developed Optimus Viper, a 200 kg rapid-response craft running the AI-driven Solstice OS, enabling 24/7 mission readiness and multi-payload operations.

Its commercial inspection services are priced at US$2–3 million per mission, about 90% cheaper than traditional alternatives and creating a new market segment in affordable orbital servicing.

SMC’s India strategy is anchored in Space MAITRI (Mission for Australia–India Technology, Research and Innovation), a flagship collaboration funded through an $8.5 million grant from the Australian Space Agency’s International Space Investment (India Projects) initiative. The mission scheduled for 2026 launch aboard NewSpace India Limited’s SSLV will carry a 450 kg Optimus spacecraft, the largest Australian-designed satellite to date. It brings together:

- Ananth Technologies for Assembly Integration & Testing (AIT) and cleanroom support in Bengaluru.

- Digantara for electro-optical payload development and space object tracking.

- NewSpace India Limited (NSIL) for launch services via SSLV.

The mission was referenced in the Australia–India Joint Prime Ministerial Statement at the G20 Summit (2023), marking a diplomatic and industrial milestone in bilateral space collaboration.

"We had to be bold to change perceptions, an Australian satellite flying on an Indian rocket with shared industry DNA.

Government support was instrumental.

- Australian Space Agency & DFAT funded and advocated for Space MAITRI.

- Investment NSW facilitated C-suite access to Indian conglomerates like Tata and L&T

- ISRO and IN-SPACe enabled technical collaboration frameworks.

In Australia, SMC is building the Optimus Factory (OF-01), an 800 m² manufacturing facility at UTS Tech Lab, Sydney operational by late 2025. This will produce 20+ spacecraft annually, supporting Australia’s “Future Made in Australia” sovereign capability agenda.

Impact & Results

Space Machines Company’s results are visible across three key dimensions, commercial performance, bilateral capability-building, and strategic influence demonstrating the tangible outcomes of a first mover in Australia–India space collaboration.

Commercially, the company has transitioned from an early-stage R&D venture into a revenue-generating orbital-servicing enterprise. Estimated 2025 revenues of US$16.4 million ($25 million) reflect its growing traction in defence and commercial markets, supported by participation in the $8.5 million Space MAITRI grant and participation in the $135 million Defence Trailblazer programme. A lean workforce of 59 employees worldwide, up 31% year-on-year, underscores SMC’s operational efficiency. These gains are reinforced by strong demand for the company’s US$2–3 million low-Earth-orbit proximity-inspection services, priced roughly 90% below traditional methods, which are creating a new commercial category in orbital asset protection.

In capability development, SMC’s investments have reshaped both the Australian and Indian space ecosystems. The Optimus Factory (OF-01), an 800 m² spacecraft-manufacturing facility at UTS Tech Lab in Sydney will come online by late 2025, representing the largest private satellite Assembly, Integration, and Testing (AIT) cleanroom in Australia. The facility is designed to produce five spacecraft simultaneously and over twenty units annually by 2026, directly advancing Australia’s “Future Made in Australia” sovereign capability agenda.

In parallel, SMC has built a circular manufacturing ecosystem that connects over 250 Indian vendors, many of whom previously supplied exclusively to ISRO, upgrading them to international commercial standards and schedules. This vendor-development programme is one of SMC’s defining contributions, creating not just hardware, but a durable bilateral industrial base for the next generation of space manufacturing.

Strategically, the Space MAITRI Mission has become a symbol of Australia–India technological partnership. Scheduled for 2026 launch aboard NewSpace India Limited’s SSLV, it will carry a 450 kg Optimus spacecraft, the largest Australian-designed satellite ever built, integrating payloads from Ananth Technologies and Digantara. The mission has been referenced in joint prime-ministerial statements at the G20, elevating SMC’s profile from start-up to national asset.

Despite this success, SMC’s cross-border operations have raised the friction that remains in bilateral policy frameworks. Repeated GST, TDS, and import-duty payments on iterative component transfers between India and Australia have inflated costs by as much as three-to-four times per subsystem, revealing a structural gap in the AI-ECTA’s implementation for high-iteration, dual-nation manufacturing. The company’s leadership continues to engage with DFAT, Austrade, and IN-SPACe to streamline these bottlenecks, positioning SMC as both participant and policy influencer in shaping the next phase of the corridor’s industrial design.

Taken together, these achievements, financial resilience, manufacturing expansion, supply-chain transformation, and strategic diplomacy underscore SMC’s evolution from a niche start-up to a catalyst for Australia’s space-sovereignty ambitions and India’s commercial-space maturity. The company’s journey proves that bilateral innovation is not only possible but essential in the emerging geopolitics of orbital infrastructure.

Lessons & Insights

Treat India as Core Strategy, not a Cost Centre

Core Takeaway

Long-term success in the corridor demands strategic integration, not opportunistic outsourcing.

From day one, Space Machines Company embedded India into its operating model, not as a back office, but as a pillar of engineering and growth. Its first employee was a former Team Indus lunar-mission engineer, symbolising a deep-rooted commitment to co-development rather than subcontracting. “You have to factor India into your overall growth, your capital, your engineering, your entire strategy, not as an afterthought.”

Navigate Hierarchies with a Top-Down Engagement Model

Core Takeaway

In India’s institutional landscape, senior-level sponsorship is non-negotiable for execution velocity.

This insight reshaped how SMC manages its partnerships with ISRO, IN-SPACe, and Indian industrial suppliers. Direct engagement with senior leadership and policy gatekeepers proved decisive in securing technical approvals, contract alignment, and program momentum.

Build Commercial Capacity, Not Just Hardware

Core Takeaway

Supplier transformation can create a more durable competitive moat than product innovation alone.

Over 250 Indian vendors, once restricted to ISRO’s internal projects, have now transitioned to serving international customers under SMC’s commercial and quality standards. This shift created an ecosystem of responsive, commercially oriented partners that now supports both Indian and Australian space manufacturing.

Anticipate Policy and Taxation Friction Early

Core Takeaway

Even under AI-ECTA, dual-nation manufacturing can face compounding compliance and cost challenges.

Despite bilateral trade liberalisation, SMC encountered repeated GST, TDS, and import-duty layers on iterative component transfers between India and Australia. These duplicative costs inflated subsystem development by up to three or four times, highlighting a misalignment between trade policy and high-frequency R&D cycles.

Secure Patient Capital and Corridor-Literate Investors

Core Takeaway

Deep-tech ventures require investors who understand both the science and the corridor’s regulatory asymmetry.

Raising capital in Australia’s small deep-tech ecosystem remains challenging. Indian investors, while abundant in US-facing ventures, are often unfamiliar with Australian structures, creating friction in cross-border funding. SMC mitigated this gap through a mix of government grants (Space MAITRI, Defence Trailblazer) and strategic co-investment discussions with Indian industry partners. This highlights the importance of designing hybrid financing models that blend public-sector support with corridor-aware private capital.

Mission-Led Collaboration Builds Trust and Momentum

Core Takeaway

Tangible projects not MoUs build credibility in bilateral innovation.

The Space MAITRI Mission became a tangible symbol of collaboration, an Australian-built spacecraft launching on an Indian rocket with shared industrial DNA. The program’s technical success and diplomatic visibility demonstrated how mission-led partnerships can accelerate ecosystem trust faster than conventional trade diplomacy.

All information has been verified from primary company submissions, official filings, interview transcripts, and secondary materials cited in the References section.

Company Snapshot

KPI Impact Snapshot