Context & Opportunity

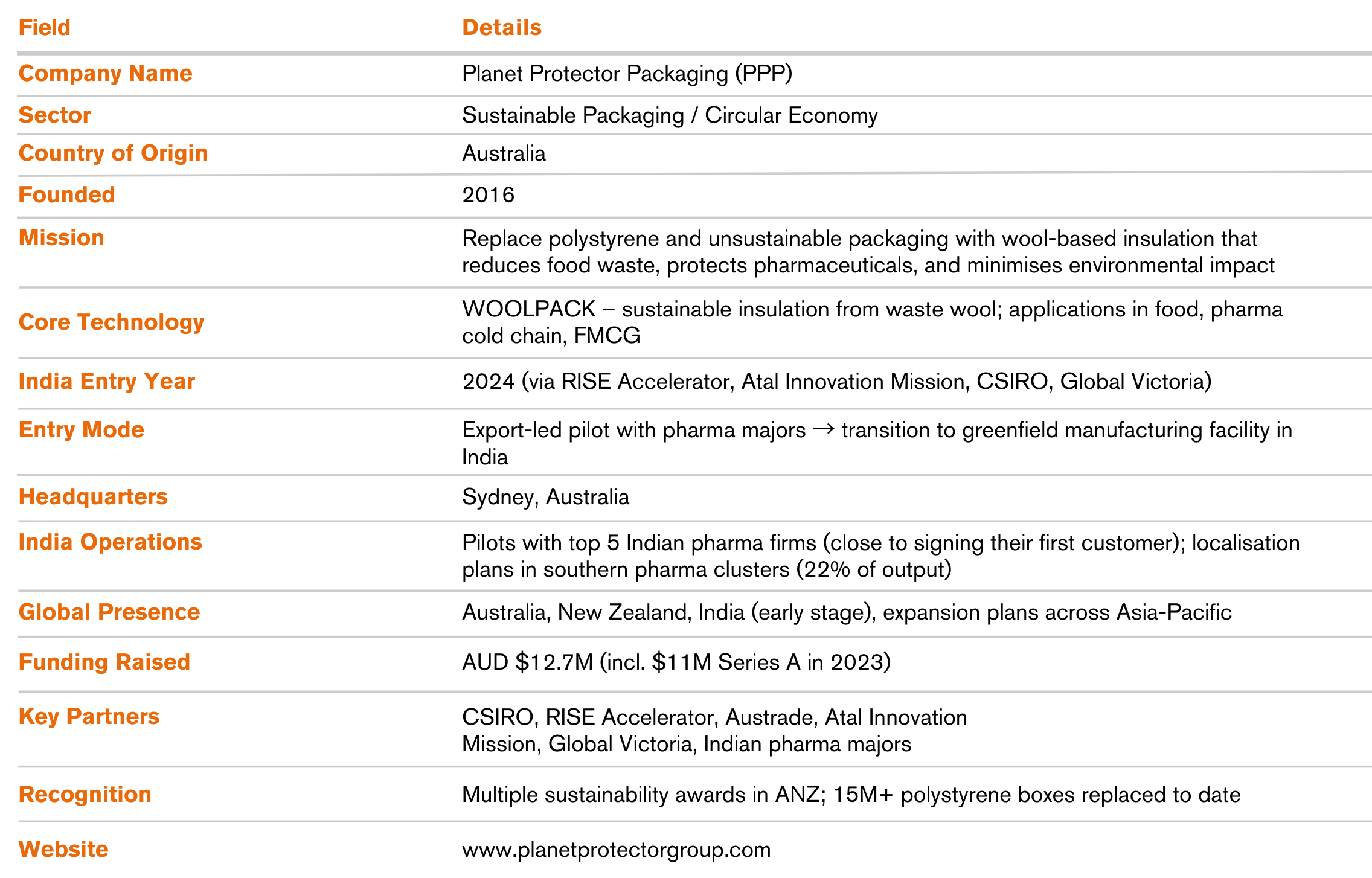

Founded in 2016, Planet Protector Packaging (PPP) has emerged as an Australian leader in circular wool-based insulation solutions, establishing a strong presence across Australia and New Zealand. Its flagship WOOLPACK range safeguards food, beverages, FMCG, and importantly pharmaceuticals, delivering superior thermal protection while reducing waste, spoilage and temperature breaches.

PPP is now expanding into India, positioning itself at the intersection of sustainability, pharmaceutical growth, and trade corridor advantages. India, as one of the world’s largest pharmaceutical hubs, generates demand for nearly 54 million tonnes of wool-based packaging annually (CAGR 8.7%). Yet, limited domestic wool supply creates a structural import dependency one reinforced by the Australia–India Economic Cooperation and Trade Agreement (ECTA), which eliminates tariffs on Australian wool. This allows PPP to leverage established supply chains in Australia and New Zealand to deliver high-quality products at globally competitive prices.

By innovatively upcycling wool waste, PPP achieves both cost competitiveness and a reduced environmental footprint, making large-scale adoption feasible for India’s pharmaceutical exporters under increasing ESG scrutiny.

Market Dynamics

- Pharmaceutical Clusters: India’s 118 pharma clusters drive production, with the southern region alone contributing ~22% of national output yet remaining underserved by sustainable packaging solutions.

- Trade & Logistics Advantage: Recent improvements in shipment infrastructure and customs clearance reduce cross-border trade frictions, enabling faster and more reliable delivery of packaging solutions.

- Policy Incentives: Central and state governments are offering land, infrastructure, and tax incentives for sustainable manufacturing, particularly in pharma-intensive geographies.

The Indian pharmaceutical sector faces intensifying regulatory and reputational pressures:

- ESG Enforcement: Sustainable procurement is becoming a compliance requirement for exporters.

- Reputational Risk: Global buyers increasingly demand planet-conscious supply chains.

- By supplying circular wool-based insulation at a competitive price point, PPP enables Indian pharma firms to meet compliance mandates while advancing sustainability commitments transforming packaging from a cost centre into a strategic ESG lever.

PPP’s entry into India is strategically timed:

- Cost Advantage: Duty-free wool imports under ECTA enhance price competitiveness.

- Scale Advantage: India’s fast-growing pharma base creates sustained demand for temperature-sensitive packaging.

- Capability Scaling: India offers a platform for PPP to build a regional hub in sustainable pharma packaging with spillover applications across FMCG and agri-exports.

For PPP, India represents both market unlocking and capability scaling. The convergence of trade liberalisation, pharmaceutical growth, ESG pressures, and logistics reforms creates a rare inflection point. If executed with localisation and cluster-based entry, PPP can establish itself as the preferred sustainable packaging partner for India’s pharmaceutical industry and beyond anchoring a new phase of circular trade and innovation in the Australia–India corridor.

Strategy & Execution

Internationalisation Strategy

Planet Protector Packaging (PPP) is pursuing a staged internationalisation strategy to enter the Indian market, deliberately sequencing an export-led pilot with a planned greenfield manufacturing build-out. This hybrid approach enables the company to de-risk entry while establishing the foundation for scalable operations across the Asia–Pacific. In its first stage, exports from Australia allow PPP to retain control over quality, demonstrate performance, and minimise upfront capital expenditure. The company is already in the process of establishing pilot projects with the country’s leading pharmaceutical manufacturers. By collaborating directly with the country’s top five pharma firms, PPP is positioning itself to validate product-market fit, build early brand presence, and establish credibility with the most influential actors in the ecosystem. Insights from this pilot phase will shape the design of a domestic greenfield hub, enabling PPP to transition into local manufacturing with greater confidence and precision.

Localisation sits at the centre of PPP’s playbook. Moving from exports to Indian production will not only enhance price competitiveness by lowering logistics costs but also address Indian customers’ preference for locally produced solutions. It will strengthen supply chain resilience through integration with regional pharmaceutical clusters and logistics corridors that anchor the cold chain ecosystem. PPP’s emphasis on hiring local talent across operations, compliance, and logistics is designed to ensure cultural alignment and regulatory agility, critical for execution in India’s complex operating environment.

At the core of PPP’s differentiation is innovation. WOOLPACK, the company’s flagship solution, is derived from waste wool and represents a sustainable, high-performance alternative to polystyrene (EPS) packaging. It reduces landfill, lowers carbon footprint, and delivers the thermal stability needed for temperature-sensitive pharmaceuticals. Importantly, WOOLPACK provides significant cost savings in supply chain and logistics. Early-stage trials are already being tailored for India’s pharma sector, with digital tools and data-driven quality monitoring deployed to maintain consistent standards across both the export and domestic phases. By aligning directly with global ESG mandates, PPP is not merely offering a packaging product but enabling Indian pharmaceutical exporters to strengthen compliance and credibility in international markets.

The execution model is structured around three phases of scaling. The first is an export-led pilot, leveraging Australian manufacturing to validate the product with leading Indian customers and secure regulatory approvals. The second is the establishment of a greenfield plant in India, creating a domestic base of operations supported by local partnerships across supply chain, logistics, and compliance. The third is a scale-up into adjacent cold-chain sectors, such as fresh produce and seafood backed by expanded distribution and integration into regional Asia–Pacific trade flows.

Public–private collaboration has been a defining feature of PPP’s India strategy. The company was selected for the RISE Accelerator Program, a bilateral initiative of the Atal Innovation Mission and CSIRO, giving it structured access to regulators, industry networks, and government platforms. As one of only six companies chosen, PPP gained credibility and visibility that have accelerated partnership discussions. Additional alignment with Make in India, Austrade, and Invest India has provided pathways for facilitation, regulatory support, and potential incentives for local manufacturing. Legal, logistics, and compliance advisory partners are further ensuring that execution is firmly rooted in Indian market realities.

PPP’s strategy rests on two calculated bets. The first is the dual-mode sequencing of exports and local production, balancing the agility of early entry with the stability of long-term manufacturing. The second is the deliberate targeting of India’s top five pharma firms to anchor early traction and influence. These moves, combined with ESG-driven branding, customer co-creation during pilots, and structured ecosystem support through bilateral accelerators, create a differentiated position in a competitive packaging landscape.

In essence, PPP’s success in India lies in its ability to combine sustainability-led innovation with deep market localisation, while leveraging government and industry platforms to accelerate credibility and scale. By marrying careful risk management with bold strategic bets, the company is positioned to transform India’s pharmaceutical cold-chain packaging landscape and establish a platform for broader Asia–Pacific growth.

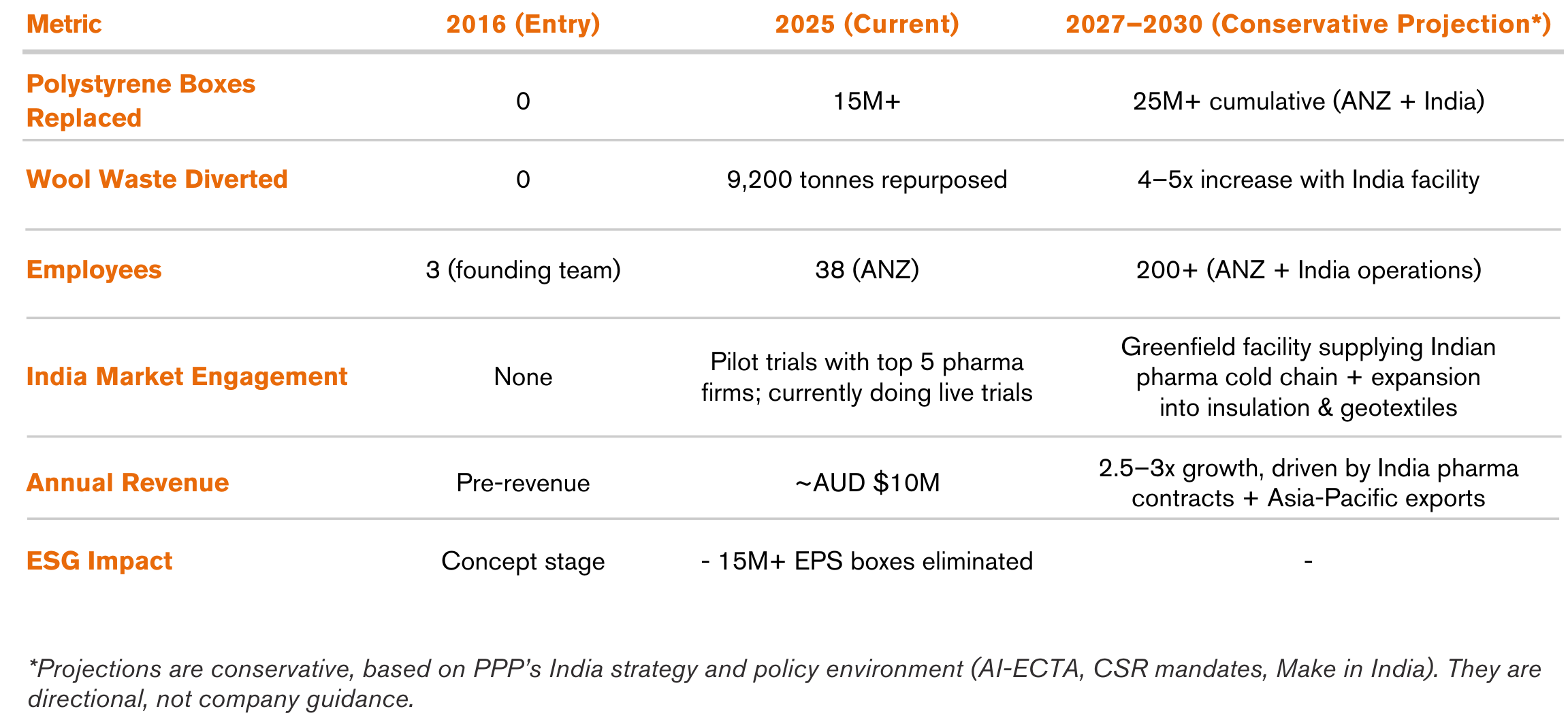

Impact & Results

Planet Protector Packaging (PPP) has established itself as a benchmark for commercial, social, and environmental value creation in Australia and New Zealand, credentials that now underpin its entry into India. Financially, the company has raised $12.7 million across two funding rounds, including a $11 million Series A in 2023, providing the capital base for accelerated scale-up. Its flagship Woolpack solution has already displaced more than fifteen million expanded polystyrene (EPS) boxes, delivering a 70 percent reduction in storage and movement costs for customers. By reducing ice-pack requirements, PPP further lowers delivery costs, while its valorisation of sheep waste wool once discarded has created an additional $14.5 million in revenue streams for Australian farmers since 2016.

Talent development has been a parallel pillar of impact. PPP’s workforce spans product development, operations, and sustainability education, embedding circular economy practices across its operations. In India, the establishment of a greenfield manufacturing facility is expected to extend this impact by generating employment in production, distribution, quality control, compliance, and logistics. By anchoring localisation in skill development, PPP is positioning itself as both a sustainability innovator and a regional employer of choice.

From an ESG perspective, PPP’s business model directly advances circularity. Waste wool is diverted from landfill, emissions are reduced, and a non-toxic manufacturing process ensures low-impact production. Social outcomes are equally tangible: PPP has enhanced the resilience of rural farming communities by creating new revenue streams, while simultaneously shifting consumer and corporate behaviour toward sustainable packaging adoption.

Strategically, PPP has evolved into a regional hub across Australasia and is now positioning India as the anchor market for South and Southeast Asia. The playbook is one of replication at scale, leveraging proven outcomes in cost efficiency, waste reduction, and farmer inclusion, while embedding these practices in new markets.

Lessons & Insights

Cultural & Communication Norms

Initial reliance on email slowed progress; WhatsApp emerged as the preferred B2B channel in India for follow-ups and coordination.

Relationship-centric engagement required patience, informal interactions, and adaptive communication.

Core Takeaway

Local communication norms are not a detail, they shape credibility, trust, and speed of execution.

Market Localisation & Micro-Market Approach

India is not a single market but a federation of micro-markets requiring tailored strategies by state, sector, and cluster.

Early engagement of local tax, legal, and compliance experts de-risked regulatory navigation.

Core Takeaway

Treating India as a collection of micro-markets, not one homogenous entity, is essential for scalability.

Operational Resilience & Supply Chain Design

Importing finished WOOLPACK products incurred duties, while local manufacturing avoids them.

This insight is driving investment in a greenfield facility to embed quality control and lower costs.

Core Takeaway

Supply-chain localisation is a strategic lever shifting from import-led pilots to domestic production unlocks competitiveness.

Circular Economy Model & ESG Advantage

PPP’s model of transforming waste wool into packaging diverted waste from landfill, reduced emissions, and supported farmers.

The circular narrative resonated with regulators, corporate buyers, and communities in India and Australia alike.

Core Takeaway

Embedding ESG outcomes into the value chain creates commercial advantage and policy legitimacy.

Partnership Ecosystem & Market Navigation

Networks such as RISE Accelerator, AIM, Global Victoria, Austrade, and CSIRO provided credibility, policy navigation, and introductions.

Local partnerships built trust and smoothed regulatory friction.

Core Takeaway

Public–private scaffolding accelerates entry and positions ventures for long-term resilience.

Broader Lesson for Cross-Border Business

Cultural humility, adaptive communication, and early local expert engagement are as critical as technology and price.

Long-term commitment, not transactional entry shapes credibility.

Core Takeaway

In emerging markets, sustained localisation and patient relationship-building are decisive for durable success.

All information has been verified from primary company submissions, official filings, interview transcripts, and secondary materials cited in the References section.

Company Snapshot

KPI Impact Snapshot