"You can install a bridge in a matter of days with a small excavator and a handful of trained people, no propping, no massive cranes, no shutdown chaos."

Context & Opportunity

InQuik is an Australian construction-technology company that emerged from six years of research and development to address one of the most entrenched challenges in bridge construction, how to deliver durable, high-quality concrete bridges quickly, safely, and cost effectively even in remote or constrained environments. The company commercialised its technology in 2017, introducing a patented modular system that integrates steel reinforcement and formwork into a single prefabricated cassette. These components are light enough to be lifted by small excavators or cranes, transported easily on flat-bed trucks, and then filled with concrete in-situ to form a single monolithic bridge element.

By 2025, InQuik had completed around 200 bridges across Australia, the Pacific, and the United States. Its products comply with Australia’s bridge code AS 5100 and are certified for up to a 150-year design life. The company’s system removes the need for temporary propping or falsework, lowers labour requirements, and dramatically reduces site disruption, a major advantage for regions with limited heavy-equipment access or short construction windows.

India presented an ideal next-stage opportunity. The country is building 12,000 to 14,000 kilometres of highways each year, and its precast-concrete bridge market is expanding rapidly as part of major programs such as Bharatmala, Sagarmala, and the Smart Cities Mission. Yet short-span bridge construction often remains slow and labour-intensive. Heavy concrete girders require 250-tonne cranes and specialised trailers, while steel trusses incur corrosion and repainting costs.

Many contractors still rely on cast-in-situ methods, leading to delays and safety risks. InQuik recognised that its lightweight, modular technology could fill this gap, but succeeding in India’s infrastructure ecosystem would require a credible local manufacturing and policy partner.

"It’s only 10% of the weight of a precast concrete element, but when you set it in position and pour, it becomes one monolithic structure that behaves like a traditional bridge

Strategy & Execution

The partnership with Tata Steel, announced publicly in June 2025, provided that anchor. Tata Steel is one of the world’s leading steel producers, with an annual crude steel capacity of 35 million tonnes. As one of the most geographically diversified players in the global steel industry, the Group operates and maintains a strong commercial presence across multiple continents. In the financial year ending 31 March 2024, Tata Steel reported a consolidated turnover of approximately US$27.7 billion, reinforcing its position as a global benchmark in scale, performance, and reach.

For Tata Steel, the alliance with InQuik fit perfectly within its strategy of moving beyond commodity steel production into downstream, value-added solutions. For InQuik, it created a route to scale and legitimacy in one of the world’s most complex procurement markets. Under the agreement, InQuik provides its proprietary designs, engineering know-how, and training materials, while Tata Steel manufactures the bridge modules in India using its downstream facilities and domestic steel grades. The relationship operates on a licensing and royalty model, giving Tata Steel exclusive production rights for InQuik´s Bridge Solution in the Indian market while maintaining InQuik’s IP control.

The two companies aligned on a phased rollout. The first phase centres on demonstration projects, small-span bridges that test performance under varying environmental conditions such as flood-prone terrain, rail corridors with restricted construction windows, and humid coastal zones.

Each bridge is designed to validate speed, durability, and constructability, collecting data on man-hours, equipment usage, and traffic downtime. This evidence-based approach aims to meet the scrutiny of public agencies such as the National Highways Authority of India (NHAI) and the Indian Roads Congress (IRC).

From the outset, InQuik and Tata Steel also focused on capability building. The partners are developing structured training and certification programs for local technicians, integrating virtual-reality modules and standardised installation procedures. The goal is to ensure quality control and safety consistency even in remote districts with limited skilled labour. This localisation of human capital is central to scaling modular bridge delivery across India’s state and national highway networks.

The India partnership follows InQuik’s disciplined internationalisation pattern: establish local proof through pilots, adapt manufacturing to national standards, and then expand regionally. In Australia and the United States, the company has already partnered with civil-engineering suppliers such as CMC and joined global forums like Constructsteel under the World Steel Association. In India, Tata Steel’s deep institutional relationships, procurement experience, and manufacturing footprint provide the industrial and policy foundation needed to mainstream modular bridge construction.

The longer this takes to reach market, the more India is at a disadvantage as a country, every month lost is thousands of bridges that could already be open.

Impact & Results

Although India’s first InQuik-Tata Steel bridges are still under construction, early results from comparable projects in Australia demonstrate the system’s ability to complete bridge superstructures within days instead of weeks. The method’s reliance on smaller machinery, minimal traffic disruption, and fewer high-risk lifting operations directly improves site safety and accessibility. For Indian conditions, where monsoons, narrow rural roads, and labour availability frequently delay projects, these efficiencies could materially change delivery schedules for small-span bridges.

The system’s structural performance has also been validated through independent certification to 150-year design life, exceeding standard concrete benchmarks. Because the modules are filled and cured in place to create monolithic decks, maintenance needs such as joint or bearing replacement or corrosion control are significantly lower than in segmented or steel truss designs. This reduction in long-term lifecycle costs aligns with India’s move toward value-based procurement and sustainable resilient infrastructure.

From a strategic perspective, the partnership enables Tata Steel to diversify into engineering solutions that directly support national priorities such as Make in India and the green-infrastructure transition. For InQuik, it secures local production, IP protection, and route-to-market scale in one of the world’s largest bridge-building environments. Together, the companies are positioned to accelerate small-span bridge delivery while improving safety, sustainability, and cost efficiency, outcomes measurable in both infrastructure and economic terms.

Lessons & insights

The InQuik–Tata Steel collaboration illustrates that high-impact innovation in infrastructure succeeds when engineering ingenuity meets institutional capacity. InQuik’s patented modular system brings proven technical efficiency, but Tata Steel’s local manufacturing, regulatory familiarity, and reputational capital make it deliverable in India’s complex public works environment. The venture shows how lifecycle economics, not just upfront cost, can reshape procurement logic; how training and standardisation turn new technology into deployable capability; and how sustainability outcomes gain traction only when quantified and tied to economic value.

All information has been verified from primary company submissions, official filings, interview transcripts, and secondary materials cited in the References section

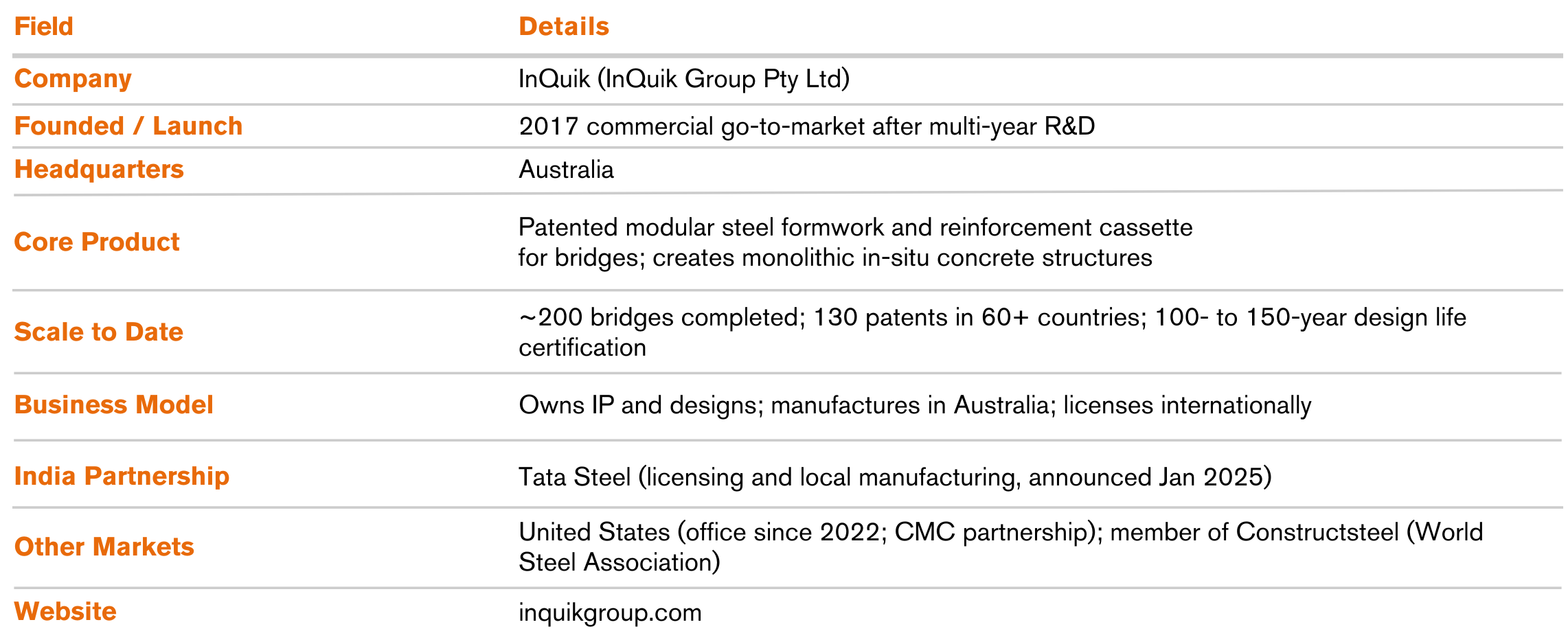

Snapshot Image

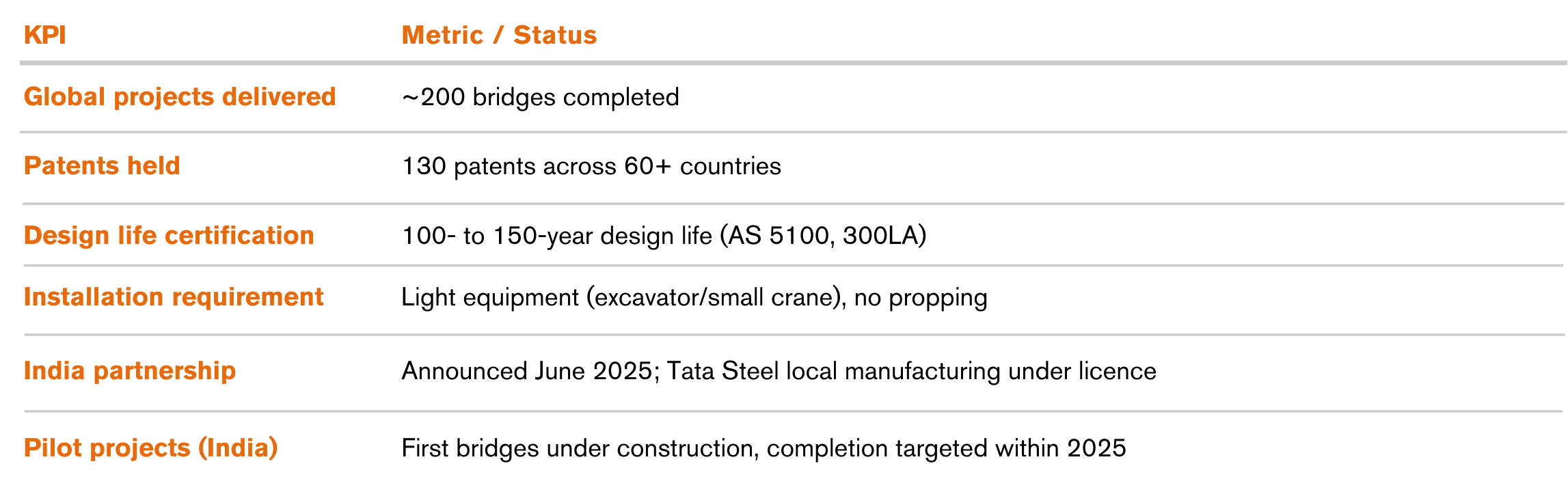

KPI Impact Snapshot