"There’s no transition without transmission. Renewables won’t matter if we can’t connect them to the grid."

Context & Opportunity

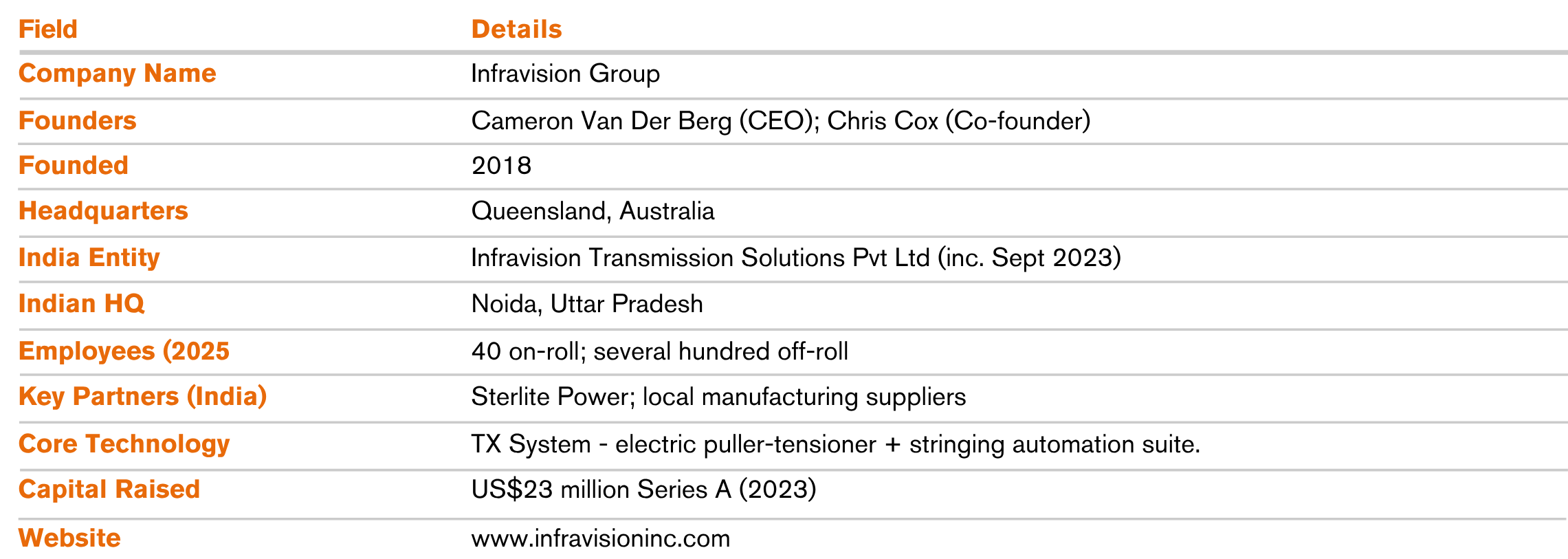

Infravision is an Australian-founded transmission-construction technology company that automates the most time-critical phase of building power lines, conductor stringing, using a combined ground–air system: an electric puller-tensioner (winch) on a trailer paired with aerial robotics and proprietary software. The company was founded in 2018 by robotics engineer Cameron Van Der Berg and military veteran Chris Cox and is used by tier-one utilities such as Transgrid (Australia) and PG&E (United States) for power line installation, maintenance and restoration.

Globally, grid build-out is now the pacing factor for renewables integration. Infravision positions its method as “the fastest, safest way to deploy power infrastructure,” with an explicit mission to make grid construction, maintenance and emergency response “10X faster, safer, and more affordable through aerial robotics.” The company reports stringing up to 765 kV, 2,000+ miles installed, and 40+ projects across 4+ countries, a base that underpins entry into large, fast-growing markets.

India is one of those markets. The government’s target of 500 GW non-fossil capacity by 2030 requires rapid transmission expansion to avoid curtailment and stranded assets, a challenge regularly highlighted by sector analyses and official planning documents. In this context, compressing stringing timelines and reducing aviation and right-of-way risk are material system enablers.

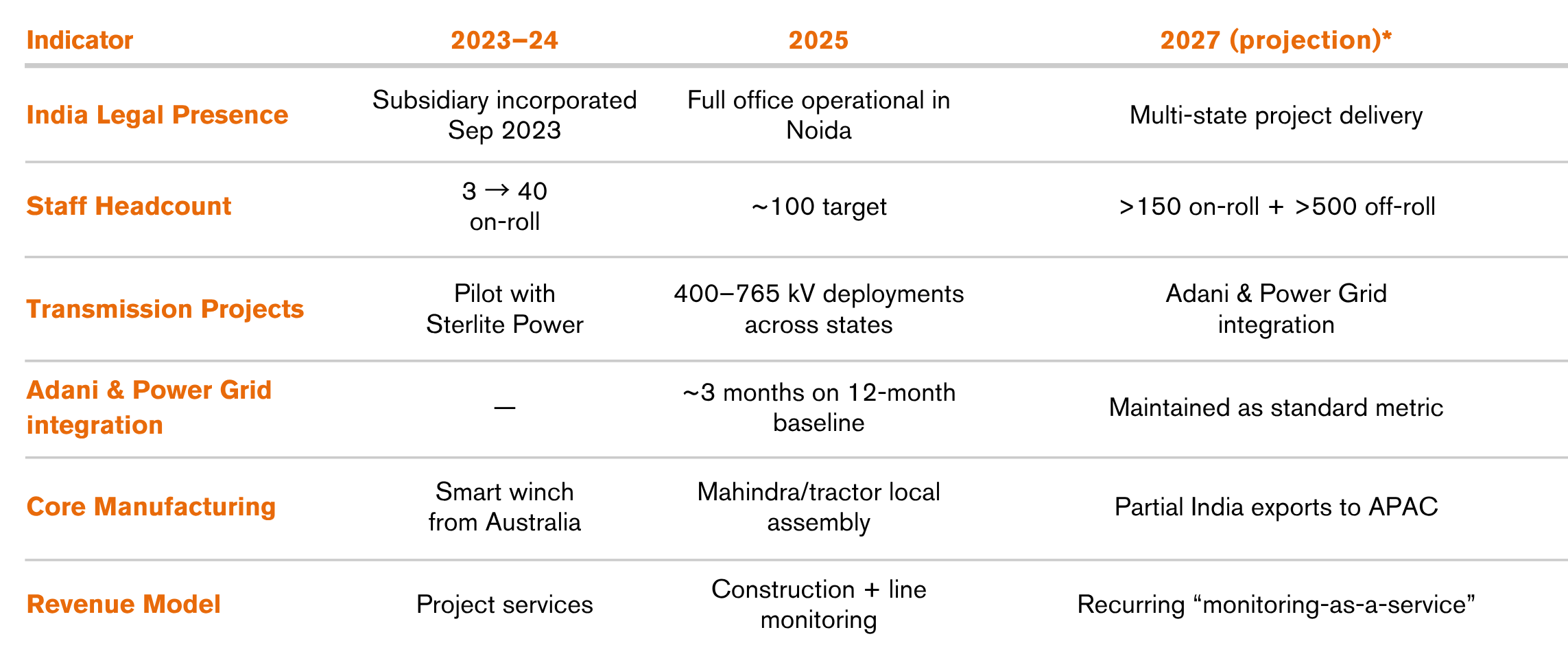

In September 2023, Infravision incorporated Infravision Transmission Solutions Pvt. Ltd. in India and, in February 2025, formally opened a Noida (Delhi-NCR) facility, inaugurated by the Governor of Queensland with a publicly stated plan to scale toward ~100 employees to support delivery.

Strategy & Execution

Infravision’s entry into India was a masterclass in sequenced localisation, start small, scale fast, and embed trust early. Its go-to-market began not with a marketing blitz but with a pilot partnership with Sterlite Power, India’s most innovation-oriented private transmission developer. That early collaboration served as a live proof point, demonstrating that automating transmission construction could cut critical-path timelines by as much as 25% and reduce right-of-way disruption on farm and urban land.

Unlike other foreign entrants, Infravision refused to replicate its Australian model wholesale. India’s terrain and regulatory environment required engineering reinvention. The core electric smart winch, Infravision’s proprietary IP continued to be manufactured in Queensland, but the delivery platform was rebuilt for India. Since tractors dominate rural mobility and cars rarely tow, the company developed a Mahindra-based VX system, later a tractor-mounted variant, modularised for narrow village roads and variable terrain. This hybrid design aligned with the Make in India agenda using local chassis, generators and line hardware while retaining Australian-made core components.

Equally strategic was the decision to build a fully owned Indian subsidiary rather than operate through a contract partner or EOR model. “We realised we couldn’t run India remotely,” by establishing a local board, hiring a country CEO and embedding legal, HR and field operations teams in Noida, Infravision moved from vendor status to trusted partner within India’s tight-knit transmission ecosystem. This structure enabled faster contracting, real-time customer interface, and compliance with complex import and labour regimes.

Localisation extended to workforce development. India’s shortage of skilled stringing technicians was solved through targeted training of technicians and field supervisors, creating jobs for young engineers in a high-tech segment of infrastructure. The team grew from a one-person beachhead in 2023 to 40 on-roll staff and hundreds of off-roll workers by 2025, with plans to double within a year. Every project acted as a live learning loop, refining deployment protocols and building the credibility needed to enter new states and work with other developers such as Power Grid and Adani.

"We had to re-invent our product for India. You can’t tow a trailer through Delhi; you mount it on a tractor.

Impact & Results

The impact of Infravision’s deployment in India is both tangible and systemic. The most visible benefit is time compression on the critical path. For a typical 12-month project, automated construction techniques can save up to three months, equivalent to tens of millions of dollars in interest-during-construction (IDC) cost for developers. Earlier commissioning also means renewable projects generate revenue sooner, improving cash flows and grid availability.

Beyond speed, the technology transforms safety and sustainability. By operating above fields without cutting new access corridors, Infravision minimises land disturbance and local opposition by reducing Right of Way complexities. Its Indian projects have demonstrated faster restart after storms and lower accident frequency, boosting both ESG and community acceptance.

The firm’s local manufacturing footprint and training pipeline have created high-value jobs in Noida and regional sites, spurring ancillary industries in component supply and maintenance. From an ecosystem view, Infravision has become a critical enabler of India’s transmission capacity addition targets, helping reduce the ~50 GW of renewables currently awaiting evacuation.

"Every month you take off a project is not just financial savings, it’s more renewable power delivered to the grid.

Lessons & Insights

Localisation Beyond Logistics

Adapting hardware to fit India’s mobility and manufacturing realities from tractor-mounted trailers to locally sourced line hardware, proved as critical as winning contracts.

Core Takeaway

Engineering local fit builds credibility faster than importing a foreign playbook.

Presence Drives Performance

Operating through an on-ground entity with Indian leadership turned Infravision from a supplier into a strategic partner.

Core Takeaway

In India, relationships outperform remote control; trust cannot be outsourced.

Patience and Partners Are Prerequisites

Navigating business compliance and early start up complexities demands local advisers and resilience. The need to “let India be India,” accepting different pace and process.

Core Takeaway

Endurance and empathy are strategic assets in market entry.

Time Saved Is Trust Earned

Shorter project cycles build developer confidence and policy trust in new methods.

Core Takeaway

In infrastructure, proof of execution is the strongest form of advocacy.

All information has been verified from primary company submissions, official filings, interview transcripts, and secondary materials cited in the References section.

Company Snapshot

KPI Impact Snapshot

Projections are directional, not formal company guidance.