" Circular Seed was founded with a singular purpose: to challenge and transform how the world deals with plastic and industrial waste, particularly in places where traditional recycling systems fail to reach."

Context & Opportunity

The global waste management industry faces structural fragilities. Conventional recycling models, designed as centralised, large-scale plants, often collapse when confronted with hard-to-recover waste streams such as multilayer films, industrial composites, and mixed polymers. These systems are further undermined in geographies marked by distance, remoteness, or underdeveloped infrastructure. The collapse of Australia’s flagship soft-plastics programs exposed these systemic vulnerabilities ranging from stockpiling and logistical bottlenecks to eroded public trust in recycling as a whole.

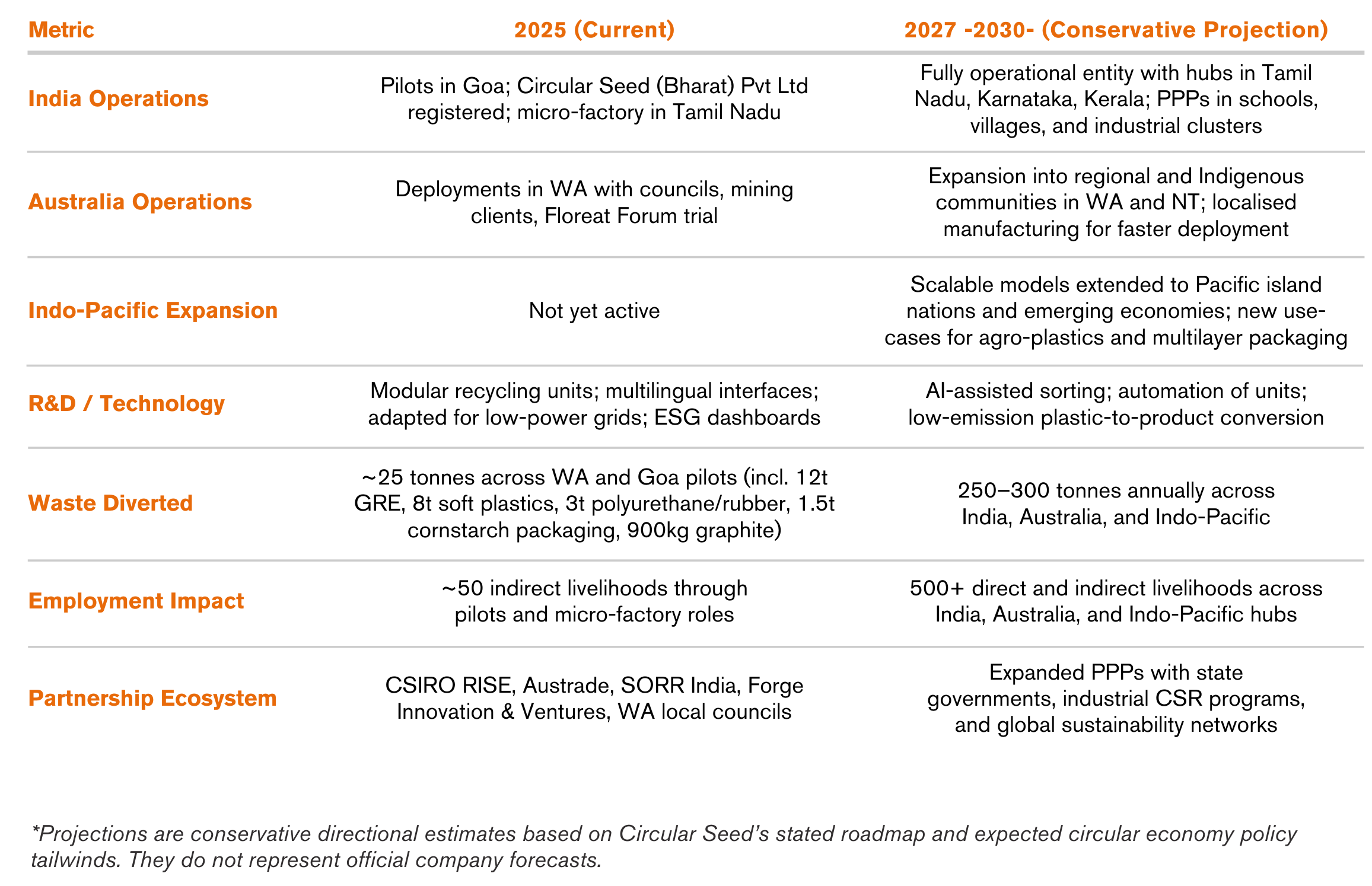

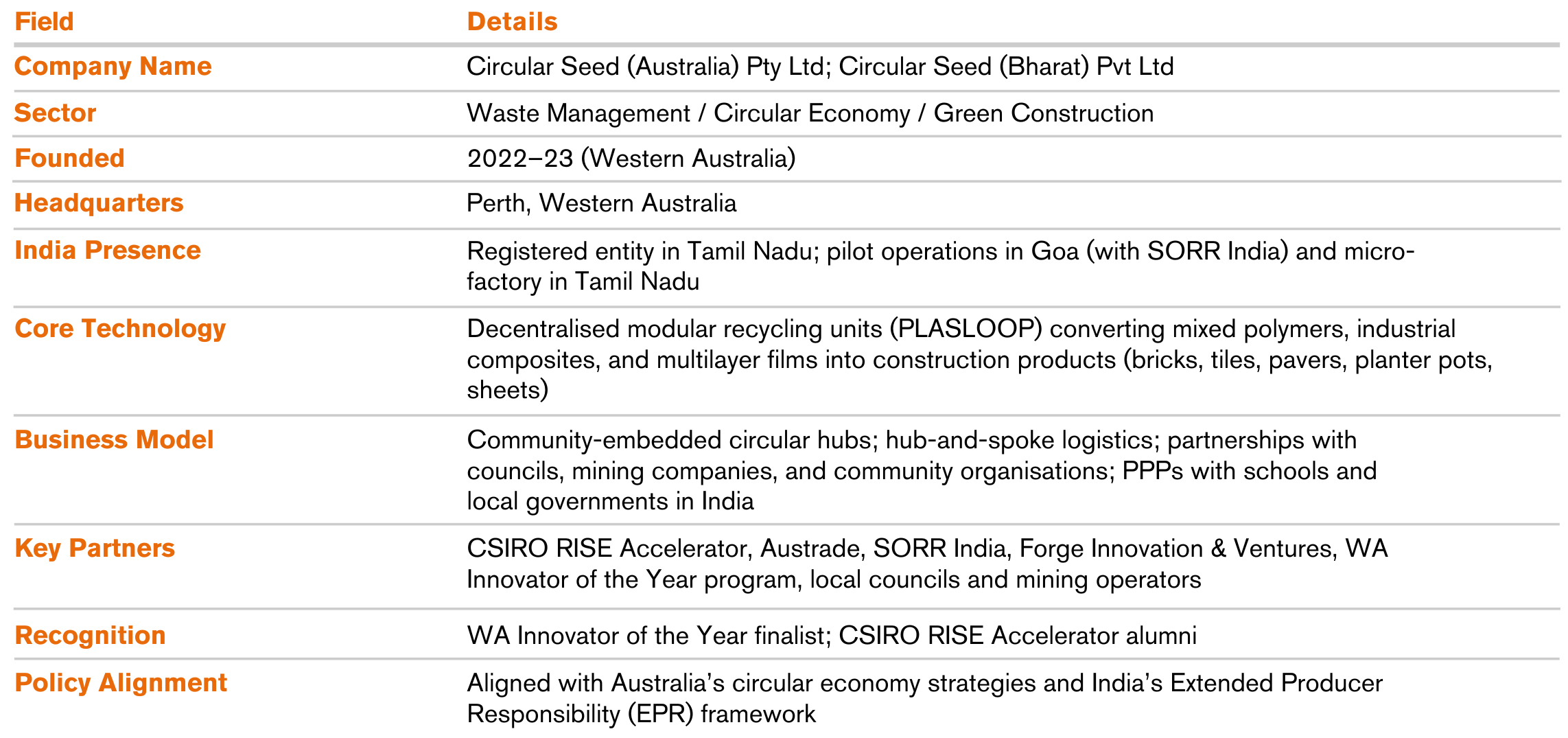

Circular Seed emerged as a response to these challenges, designing a decentralised, modular model that localises circularity at the point of waste generation. Its technology transforms problematic waste once destined for landfill or incineration, into durable construction products such as bricks, tiles, pavers, planter pots, and building sheets. The company’s model is reinforced by regulatory alignment: in Australia, with evolving circular economy strategies and procurement mandates; and in India, with the Extended Producer Responsibility (EPR) framework, which obliges producers to close material loops. The opportunity spans mining, manufacturing, coastal communities, and regional towns where on-site recycling capacity is absent, but demand for sustainable building products is growing.

Strategy & Execution

Phased entry model

Phased, partnership-driven entry has been central to Circular Seed’s expansion. In Australia, the company incorporated as a private entity in Western Australia, engaging directly with mining companies, regional councils, and industrial operators. Participation in the CSIRO RISE Accelerator and recognition as a WA Innovator of the Year provided credibility, accelerated access to government networks, and unlocked early clients. A hub-and-spoke logistics model, anchored in Perth, allowed standardisation of modular units and efficient deployment into remote resource communities.

In India, Circular Seed began with a pilot initiative in Goa through SORR India & CSR Bharat Network, adapting its technology and engagement approach to local contexts. This was followed by the establishment of Circular Seed (Bharat) Private Limited in Tamil Nadu, accelerated by Forge Innovation & Ventures. This progression allowed the company to de-risk its entry, gain fluency in India’s regulatory frameworks, and scale its reach across Goa, Tamil Nadu, Karnataka, and Kerala.

Technology adaptation underpinned execution in both markets. In Australia, modules were integrated with automated data logging, safety interlocks, and ESG-compliant dashboards features demanded by institutional clients for procurement compliance and sustainability reporting. In India, interfaces were redesigned with multilingual graphic displays to suit semi-skilled operators, machines were downrated for low-voltage power grids and limited site footprints, and outputs were tailored to local construction practices, ensuring relevance and adoption.

Operational learning accelerated evolution. In Western Australia, stakeholder demand broadened the scope of pilots from industrial clients to include community training programs and council-led demonstration units. In Goa, infrastructure constraints spurred co-design workshops that produced a flexible, school-deployment model later replicated in coastal and rural settings to integrate education, livelihoods, and recycling outcomes.

At the centre of execution was an ecosystem of partnerships. Global platforms such as the CSIRO RISE Accelerator and Austrade provided policy frameworks and credibility, while local partners such as SORR India and Forge Innovation & Ventures ensured cultural adaptation, site selection, and workforce training. This dual structure allowed the company to combine top-down government support with bottom-up community ownership.

Risk management was framed through a dual-market lens. Resource allocation was balanced between Australia and India, while the modular, IP-driven platform provided flexibility and embedded monitoring tools. Rather than attempting to eliminate uncertainty, Circular Seed embraced adaptive learning, turning risk into a catalyst for resilience and innovation.

"Our modular, decentralised units turn discarded soft plastics, polyurethane, and industrial offcuts into useful products like bricks and tiles bringing circularity directly to the point of waste generation.

Impact & Results

Circular Seed’s decentralised systems have already diverted tens of tonnes of waste from landfill, while simultaneously creating economic and social value.

- In Western Australia, the company recovered over 900 kg of graphite, 1.5 tonnes of cornstarch packaging, 12 tonnes of glass-reinforced epoxy (GRE), 3 tonnes of polyurethane, rubber, and embedded metals, and 8 tonnes of soft plastics and multilayer films. These streams were transformed into thousands of bricks, pavers, tiles, and planter pots.

- At the Floreat Forum trial, nearly 1,000 kg of soft plastics were processed into 610 paver bricks within weeks, under conditions of full transparency and zero stockpiling.

- In the Goa Coastal Initiative, fisherfolk collected ocean plastics that were processed onshore, integrating recovery into STEM education curricula and livelihood programs. The PLASLOOP units deployed here demonstrated higher recovery rates and deeper community engagement than conventional collection methods.

Beyond material recovery, the company has catalysed inclusive green employment in sorting, shredding, moulding, and maintenance. In India, a micro-factory in Tamil Nadu has been established, and in both countries transport emissions have been cut through on-site processing that eliminates long-haul waste movement. Industrial clients benefit from new revenue streams through circular material recovery, while communities gain tangible assets, new skills, and local resilience.

Circular Seed has proven that waste can be reimagined as a feedstock for growth, not a liability to manage. By embedding modular systems into industrial and community ecosystems, the company has demonstrated how decentralisation can overcome the fragilities of traditional recycling models. Its dual-market strategy, anchored in Australia’s policy frameworks and India’s EPR-driven demand, positions Circular Seed at the forefront of circular manufacturing innovation, with potential to scale across the broader Asia–Pacific.

"Pilots are not just proofs of technology, they are trust-building exercises that must be deeply embedded in local context.

Lessons & Insights

Market Entry & Strategy

Entry into India highlighted the importance of early entity formalisation to enable smoother procurement, CSR alignment, and government partnerships.

Bilateral collaboration with SORR and Forge Innovation & Ventures reinforced that start-ups gain credibility faster when leveraging trusted local partners.

Core Takeaway

Early local incorporation and bilateral partnerships accelerate legitimacy and reduce market-entry friction.

Technology & Product Strategy

Modular portfolios of pre-configured systems reduced engineering overhead and enabled faster deployments compared to bespoke builds.

Tailoring interfaces and outputs to market-specific needs (data dashboards in Australia, simplified multilingual visuals in India) improved adoption.

Core Takeaway

Standardised modularity paired with local customisation balances scalability with relevance.

Branding & Stakeholder Engagement

Underinvestment in communications limited early visibility and slowed stakeholder buy-in.

Strategic storytelling, particularly around community empowerment and circular economy value, proved essential to unlock partnerships.

Core Takeaway

Purpose-driven ventures must amplify their narrative to convert technical success into stakeholder traction.

Cultural Calibration

Australia prioritised compliance, ESG dashboards, and data integrity.

India demanded relational trust, inclusivity, and simplicity in design.

Core Takeaway

Cross-market strategies must adjust for cultural decision-drivers, what signals credibility in one market may not resonate in another.

Pilots as Trust-Building

Pilot projects proved most effective when they embedded co-creation with communities and empowered local champions, rather than operating as technical demonstrations alone.

Core Takeaway

Pilots build trust when they are structured as community partnerships, not proof-of-technology exercises.

Risk & Adaptability

Circular Seed embraced uncertainty, using iterative learning to refine deployment models in both Australia and India.

Regulatory and logistical barriers were mitigated through adaptive risk posture and distributed partnerships.

Core Takeaway

Pilots build trust when they are structured as community partnerships, not proof-of-technology exercises.

Broader Lesson for Cross-Border Business

Circular Seed demonstrates that cross-border innovation is not about exporting a product, but about localising circular systems, building legitimacy through partnerships, and embedding community value.

Core Takeaway

Community-led circular innovation succeeds when global technology is matched with patient localisation, storytelling, and ecosystem support.

All information has been verified from primary company submissions, official filings, interview transcripts, and secondary materials cited in the References section.

Company Snapshot

KPI Impact Snapshot