Context & Opportunity

Established in 1974 in Melbourne, Australia, ANCA CNC Machines emerged as a response to a critical market need for precision, flexibility, and automation in tool manufacturing. Co-founders Pat Boland and Pat McCluskey initiated the venture with a clear vision: to develop the world's most advanced tool grinding technology.

From its modest inception in a small garage, ANCA has evolved into a global leader in CNC tool and cutter grinders. The company's international success is evidenced by its expansion into over 45 countries, with offices in the UK, Germany, China, Thailand, India, Japan, Brazil, Tiawan and the USA, complemented by an extensive network of representatives and agents worldwide.

ANCA's product portfolio caters to diverse industry demands, serving core sectors such as automotive, aerospace, die and mould, medical, energy, mining, and 3C industries.

The company's unique value proposition lies in its comprehensive ecosystem, including machines, software, and automation solutions. This integrated approach enables clients across various industries to enhance productivity, minimise waste, and optimise operations.

"Founded in 1974 in Melbourne, Australia, ANCA CNC Machines was established by Pat Boland and Pat McCluskey with a clear mission: to create the world's most advanced tool grinding technology.

- Johanna Boland, Group Strategy & Communications Manager, ANCA CNC Machines

Strategy & Execution

ANCA first served India via distributors in the 2000s; it then incorporated ANCA Machine Tools Pvt. Ltd. in 2012 and established a direct presence in Bengaluru. It recognised India's potential as a rapidly industrialising nation with a skilled workforce and growing demand for precision tooling. ANCA's strategy was rooted in a data-driven approach, utilising CRM analytics, competitor benchmarking, customer interviews, industry reports, and trade data to inform decision-making.

The execution of ANCA's market entry strategy was carefully phased. Initially, the company entered through a local distributor, leveraging existing regional expertise and networks. As market demand grew and ANCA's installed base expanded, the company transitioned to a direct presence model, establishing its own office and technical center in Bangalore. This approach allowed ANCA to maintain full control over service quality and customer engagement.

To ensure internal alignment and mitigate risks, ANCA implemented transparent communication of opportunities, detailed ROI projections, and cross-functional involvement in the planning process. The company also initiated pilot programs to test and refine its approach in the Indian market. ANCA made strategic adjustments to enhance its competitiveness in India, including modifying its pricing model, localising packaging, introducing custom marketing materials – such as an ANCA India What’s App channel; and diversifying distribution and support networks.

These adaptations were crucial in tailoring ANCA's offering to the specific needs and preferences of the Indian market. The company's branding strategy focused on establishing thought leadership. ANCA conducted technical seminars, participated in trade shows like IMTEX, launched digital campaigns, and offered one-on-one demonstrations at its Bangalore Technology Centre. These efforts significantly boosted market awareness and positioned ANCA as a trusted name in precision tool grinding within the Indian market.

"In India, we followed this model, initially working with a distributor, then setting up our own office and technical centre in Bangalore.

- Jake Farragher, General Manager – Asia.

As ANCA's presence in India grew, the company successfully transitioned from its initial distributor partnership to a direct engagement model. This shift allowed ANCA to strengthen customer relationships, provide tailored support, and maintain greater control over its brand and service delivery. The company built a strong, locally managed team in India that was fully integrated with its global operations. To ensure access to top engineering talent, ANCA implemented a strategic recruitment approach. This included partnerships with academic institutions, participation in job fairs, and rigorous screening processes. This approach allowed ANCA to build a skilled workforce capable of supporting its growth and maintaining its high standards of innovation and quality in the Indian market.

"ANCA is now one the top three CNC tool grinder suppliers in India, achieving doubler digital annual growth."

Impact & Results

ANCA's market entry strategy yielded significant positive outcomes across multiple dimensions. The company's success was quantified through key metrics including market share growth, reduced service lead times, and improved customer satisfaction scores. These performance indicators were consistently tracked and communicated to both internal and external stakeholders via reporting dashboards, case studies, and trade press coverage.

The expansion was primarily funded through retained earnings, supplemented by Australian government export development grants. ANCA implemented a long-term approach to measuring return on investment, focusing on a 3-5 year horizon. This strategy proved successful, with the company achieving positive returns driven by strong revenue growth and optimised local cost structures.

Risk management played a crucial role in ANCA's expansion. A comprehensive risk matrix was developed, encompassing operational, regulatory, financial, and reputational risks. Contingency plans were put in place, including the identification of alternate suppliers, foreign exchange hedging strategies, and scenario planning for potential policy shifts or regulatory changes.

ANCA closely monitored a range of key performance indicators (KPIs) to inform strategic decision-making. These KPIs included order volume, lead times, customer acquisition cost (CAC), customer satisfaction scores, and service response times. This data-driven approach allowed for agile adjustments in sales support, inventory planning, and resource allocation.

While initial customer acquisition costs were elevated due to market entry investments, they decreased significantly as local teams and infrastructure were established. Notably, customer lifetime value exceeded expectations, driven by strong retention rates, frequent upgrade purchases, and consistent demand for ongoing services.

Technological advances played a pivotal role in ANCA's success. The introduction of the ToolRoom software significantly reduced tool design and cycle times. AI-driven corrections extended tool life, while the ULTRA machine series delivered superior precision, including essential Class A surface finishes.

ANCA's commitment to industry development and skill enhancement was demonstrated through initiatives such as their flagship toolmaking competition, which attracted entries from leading manufacturers. The company also reintroduced the Female Mechanist Award in 2025, promoting diversity and inclusion in the machining industry.

The impact of ANCA's advanced CNC technology on the Indian cutting machine landscape was transformative. Local manufacturers, previously limited in their capabilities, were now able to achieve levels of precision and efficiency comparable to global industry leaders. For instance, Bangalore-based SST Cutting Tools reported remarkable improvements in efficiency, accuracy, and turnaround times. Similarly, Pune-based Orient Tools Pvt. Ltd. leveraged ANCA's solutions to serve demanding industries such as aerospace and electronics, significantly expanding their market reach and capabilities.

Lessons & Insights

Market Entry & Strategy

Overcame early supply chain bottlenecks through partnerships with experienced logistics providers and a regional warehousing network.

Deployed regional offices and service teams across key industrial hubs to manage India’s geographic scale and diverse customer needs.

Core Takeaway

A decentralised, locally responsive operating model is essential to win in a vast and varied market like India.

Government and ecosystem leverage

Benefited from AI-ECTA tariff reductions and easier access to Indian manufacturing hubs.

Continued challenges remain in navigating GST inconsistencies, import bottlenecks, and bureaucratic approvals.

Core Takeaway

Trade agreements can improve competitiveness, but regulatory frictions require dedicated compliance and advocacy capacity.

Market positioning and customer strategy

Achieved double-digit growth and top three supplier status by emphasising direct customer engagement, training, and strong after-sales service.

Flexible pricing and modular product configurations allowed ANCA to align with India’s cost-sensitive yet quality-driven industrial base.

Core Takeaway

In India, precision and reliability must be matched by service, training, and adaptability to local pricing realities.

Organisation and capability building

Built a strong local team, hiring experts across legal, compliance, and service to meet regulatory and operational challenges.

Cultural onboarding and local leadership (regional GM and oversight committee) ensured strategic alignment with global headquarters while empowering local decision-making.

Core Takeaway

Embedding local leadership and compliance capability strengthens resilience and ensures long-term relevance.

Broader lesson for cross-border business

Digital transformation (IoT-enabled machines, predictive analytics) created a competitive edge in customer service and performance optimisation.

India’s scale and complexity shaped ANCA’s global strategy, reinforcing the importance of cultural adaptation, after-sales excellence, and infrastructure investment in other emerging markets.

Core Takeaway

Emerging markets demand patience, trust-building, and a service-first approach — technology alone is not enough.

All information has been verified from primary company submissions, official filings, interview transcripts, and secondary materials cited in the References section.

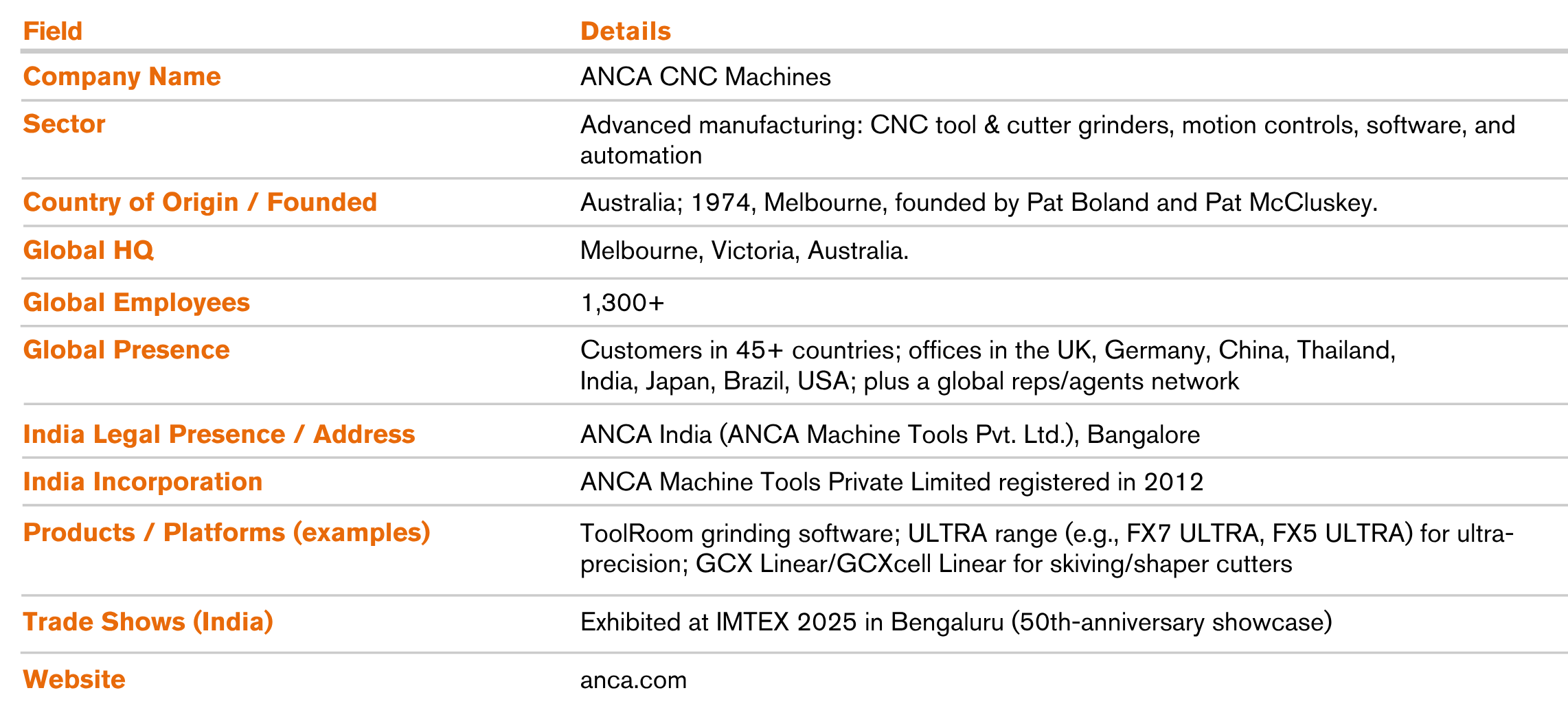

Company Snapshot

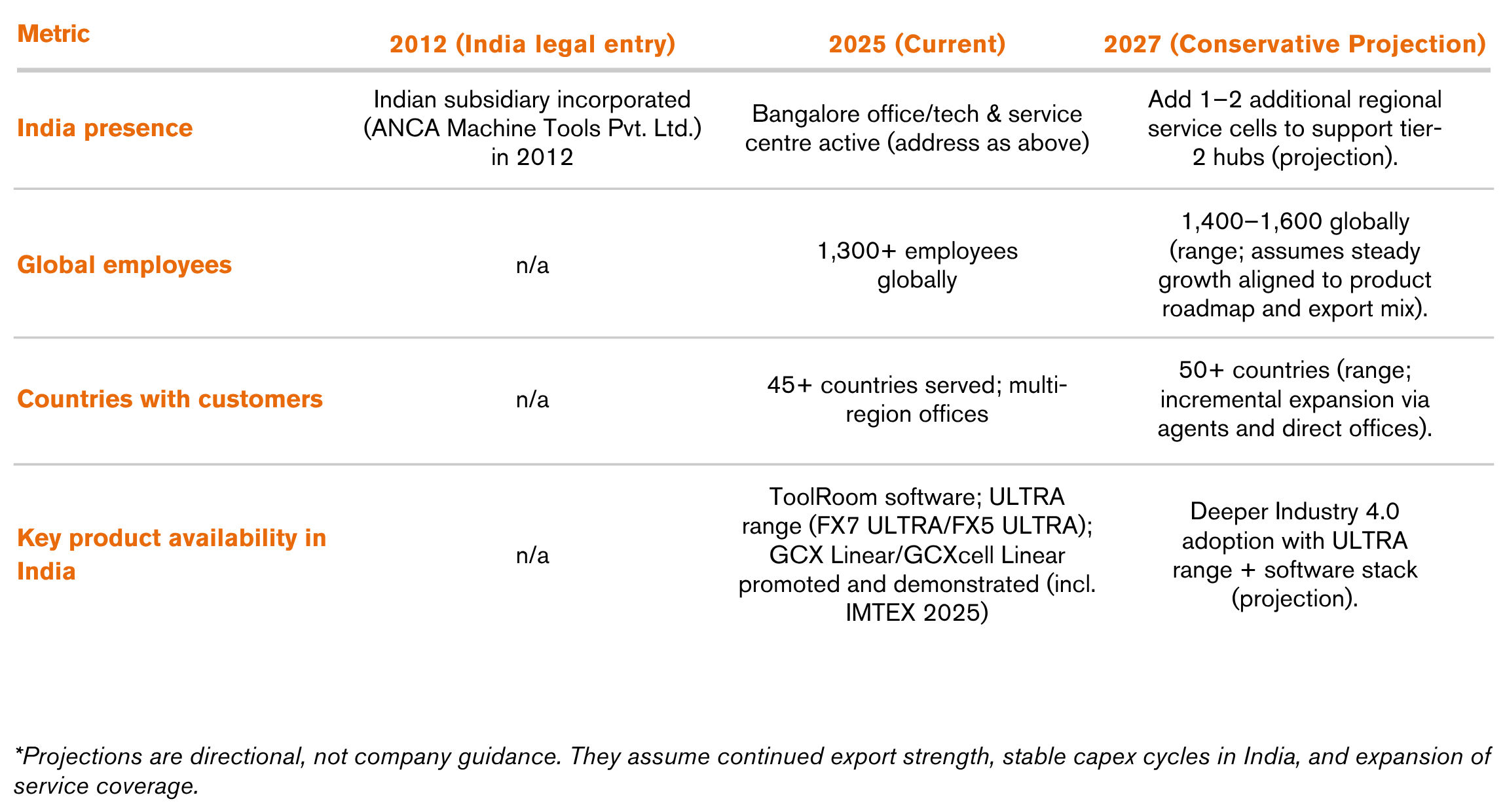

KPI Impact Snapshot